Condensing units

Condensing units UI

FEATURES

- Switchboard terminal block with provision for remote control.

- All compressors are equipped with crankcase preheating resistor.

- Semi-hermetic compressors are equipped with a thermistor; a differential oil protection pressure switch is installed on models equipped with an oil pump.

- Compressors with displaced volume above 52 m3 /h are part-winding type starting.

- All units are equipped with adjustable low-pressure and high-pressure switches in accordance with the “Pressure Equipment” Directive 2014/68/EU.

- Panel equipped with pressure switches and service outlets accessible while the machine is running.

- Liquid indicator.

- All models are supplied with liquid receiver with safety valve, in accordance with the “Pressure Equipment” Directive 2014/68/EU.

- Liquid separator on the suction line.

- Condenser fan control pressure switch. On request, it can be replaced by the electronic variable speed drive of the condenser fans.

- Installation of the condenser unit on the floor outside the cell.

- Guides for lifting forks in the lower part of the body of condensing units of Forms 3I3-3I5-5I4-5I5-6I4-7I5-8I4-8I5.

- Piping connections from the condensing unit to an evaporator are made without welding glands or flanges.

- Weather protection cover.

| TN | TB | PL | FR | |

|---|---|---|---|---|

| Temperatura cella | -5/-15 °C | -25/-35 °C | -5/-15, -25/-35 °C | -35/-45 °C |

| Potenza frigorifera | 2581 / 113684 W | 1510 / 81070 W | 1908 / 95763 W | 3705 / 49801 W |

| Volume cella | – / – m³ | – / – m³ | – / – m³ | – / – m³ |

MODEL VARIANTS

PRODUCT INFORMATION

Technical Data

Description

Accessories

Technical Data

Cell temperature

TN +5/-5 °C

TB -18/-25 °C

PL +5/-5, -18/-25 °C

FR -25/-40 °C

TN +5/-5 °C

TB -18/-25 °C

PL +5/-5, -18/-25 °C

FR -25/-40 °C

Power

1500 ÷ 113000 W

1500 ÷ 113000 W

Gas

R452A, R448A,R4449A

R452A, R448A,R4449A

High temperature

+5 ÷ +15

+5 ÷ +15

Average temperature

+5° ÷ -5°

+5° ÷ -5°

Freezer

-25 ÷ -35

-25 ÷ -35

Low temperature

-18° ÷ -25° C

-18° ÷ -25° C

Description

- Switchboard terminal block with provision for remote control.

- All compressors are equipped with crankcase preheating resistor.

- Semi-hermetic compressors are equipped with a thermistor; a differential oil protection pressure switch is installed on models equipped with an oil pump.

- Compressors with displaced volume above 52 m3 /h are part-winding type starting.

- All units are equipped with adjustable low-pressure and high-pressure switches in accordance with the “Pressure Equipment” Directive 2014/68/EU.

- Panel equipped with pressure switches and service outlets accessible while the machine is running.

- Liquid indicator.

- All models are supplied with liquid receiver with safety valve, in accordance with the “Pressure Equipment” Directive 2014/68/EU.

- Liquid separator on the suction line.

- Condenser fan control pressure switch. On request, it can be replaced by the electronic variable speed drive of the condenser fans.

- Installation of the condenser unit on the floor outside the cell.

- Guides for lifting forks in the lower part of the body of condensing units of Forms 3I3-3I5-5I4-5I5-6I4-7I5-8I4-8I5.

- Piping connections from the condensing unit to an evaporator are made without welding glands or flanges.

- Weather protection cover.

Accessories

Electric panel heater Solid body type filter on liquid line.

Only available on certain shapes. For more information, contact us!

Fan speed regulator Condenser fan speed regulator.

Only available on certain shapes. For more information, contact us!

Different voltage Solenoid valve on the delivery line.

*Only available on certain shapes. For more information, contact us!

Water condensation Pre-loaded hose and electric cable (connection between condensing and evaporating units) length 10 m.

Voltage monitor Pre-loaded hose and electric cable (connection between condensing and evaporating units) length 10 m.

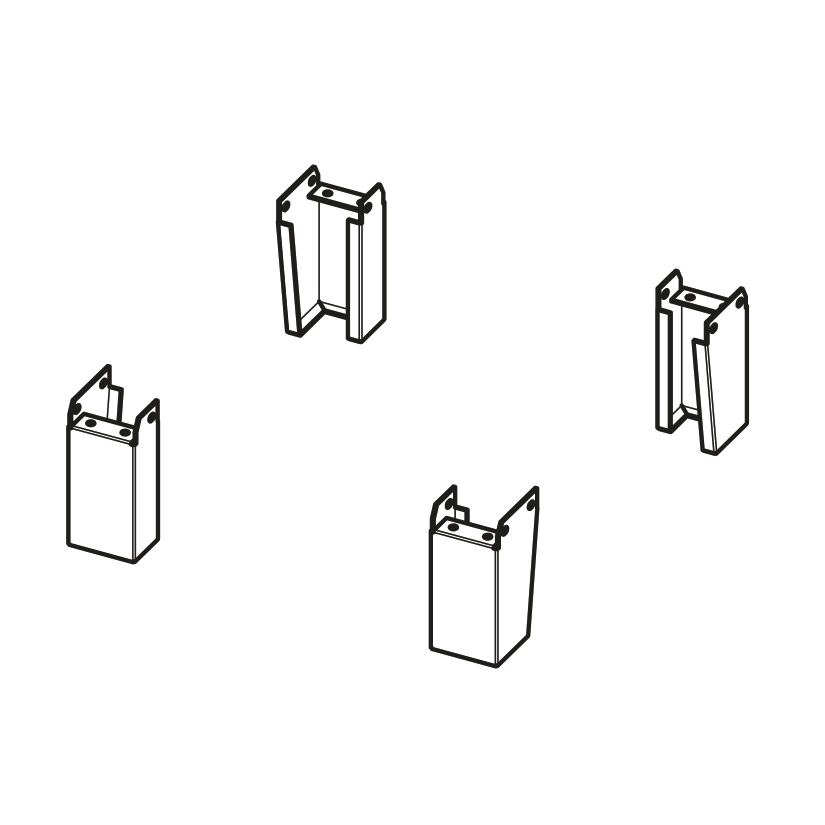

Snow protection Support feet for lifting from the ground.

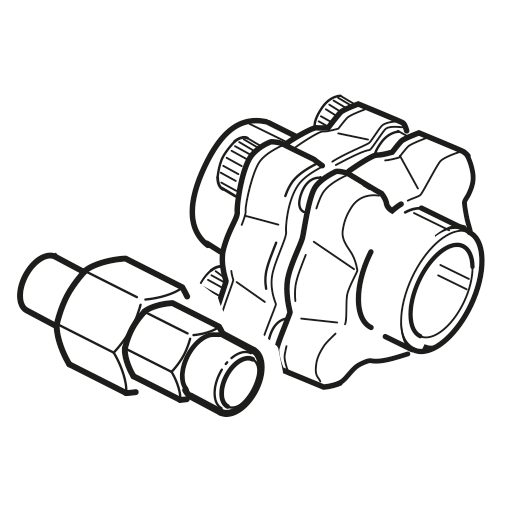

Fittings for connecting OV, BI, UC, UI Fittings for connecting liquid and suction lines for the OV, BI, UC, UI series.

Pressure gauges Electrical box with IP65 protection, fixed next to the finned coil, containing the terminal blocks for connecting fans, resistors, solenoid valve, and temperature probes.

The aforementioned components are completely wired to the relevant terminal blocks.

- Switchboard terminal block with provision for remote control.

- All compressors are equipped with crankcase preheating resistor.

- Semi-hermetic compressors are equipped with a thermistor; a differential oil protection pressure switch is installed on models equipped with an oil pump.

- Compressors with displaced volume above 52 m3 /h are part-winding type starting.

- All units are equipped with adjustable low-pressure and high-pressure switches in accordance with the “Pressure Equipment” Directive 2014/68/EU.

- Panel equipped with pressure switches and service outlets accessible while the machine is running.

- Liquid indicator.

- All models are supplied with liquid receiver with safety valve, in accordance with the “Pressure Equipment” Directive 2014/68/EU.

- Liquid separator on the suction line.

- Condenser fan control pressure switch. On request, it can be replaced by the electronic variable speed drive of the condenser fans.

- Installation of the condenser unit on the floor outside the cell.

- Guides for lifting forks in the lower part of the body of condensing units of Forms 3I3-3I5-5I4-5I5-6I4-7I5-8I4-8I5.

- Piping connections from the condensing unit to an evaporator are made without welding glands or flanges.

- Weather protection cover.